Slide title

Write your caption hereButton

About Us

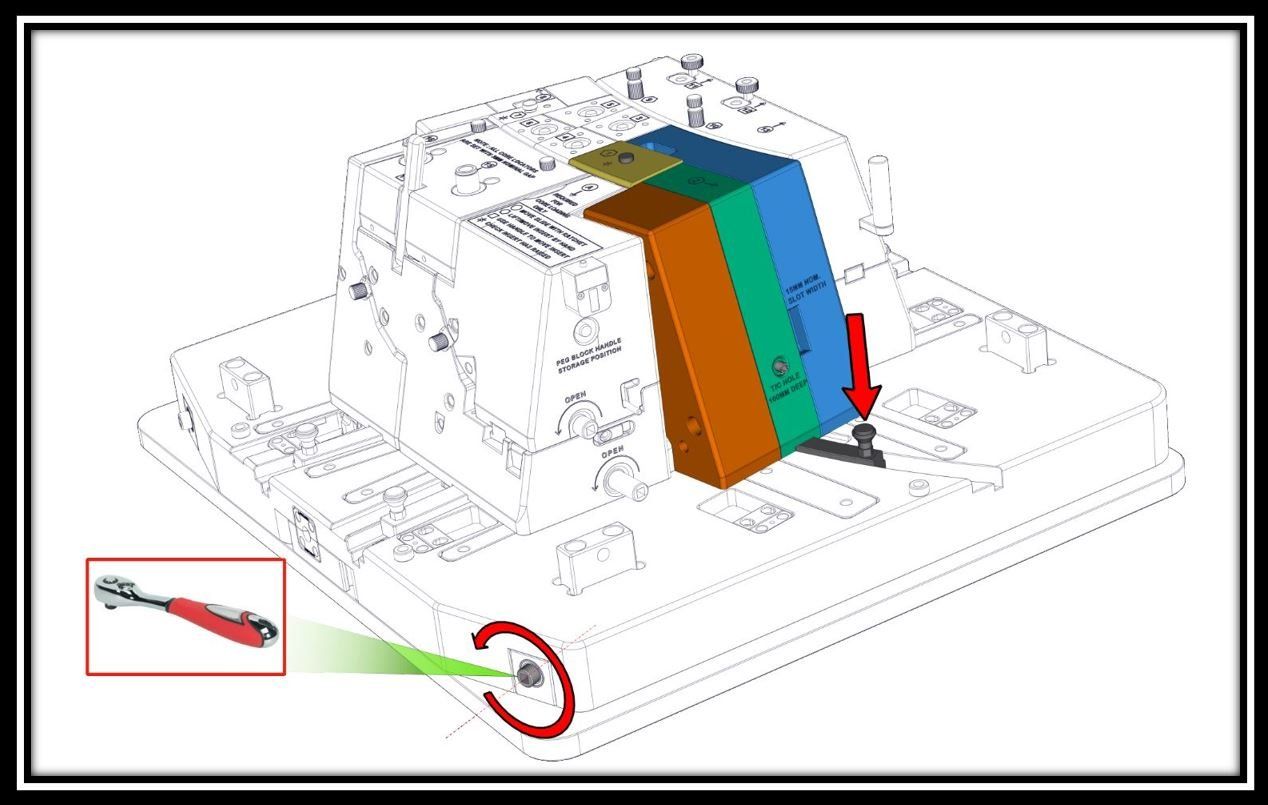

Established in 2015, Investment Tooling Technologies LTD specializes in the manufacture of high precision tooling for the power generation sector utilizing the lost wax process.

We pride ourselves in the quality and reliability of our products and innovative design concepts. We place a high value on meeting our commit dates while providing transparent program management.

We are located in a modern 9000 square foot factory in Leominster, United Kingdom, with modern machinery and capacity to support large tool builds.

Each of our employees are trained to the highest standard and have many years of experience in the industry.

Investment Tooling is certified to ISO9001:2015

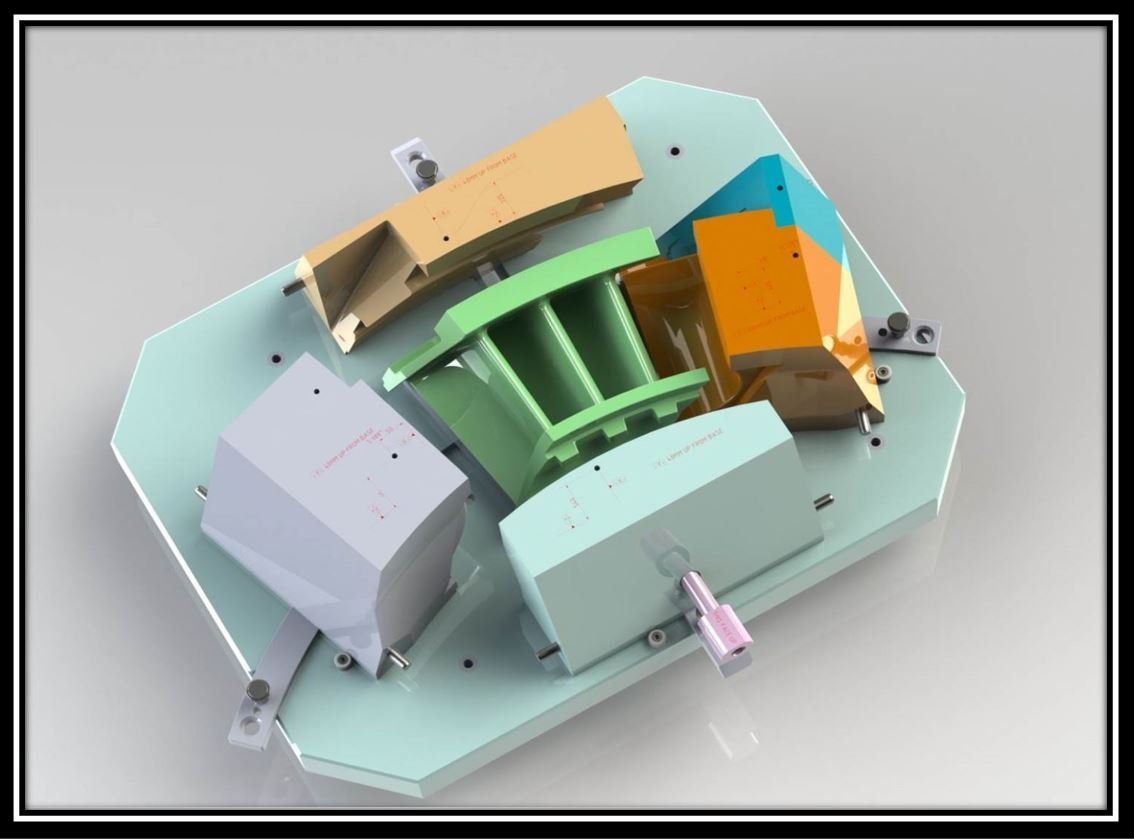

Our design team has many years of tool design experience for Structural parts and IGT blades and vanes. We utilize the latest hardware and software using Solidworks for modelling tool design around customer parts.

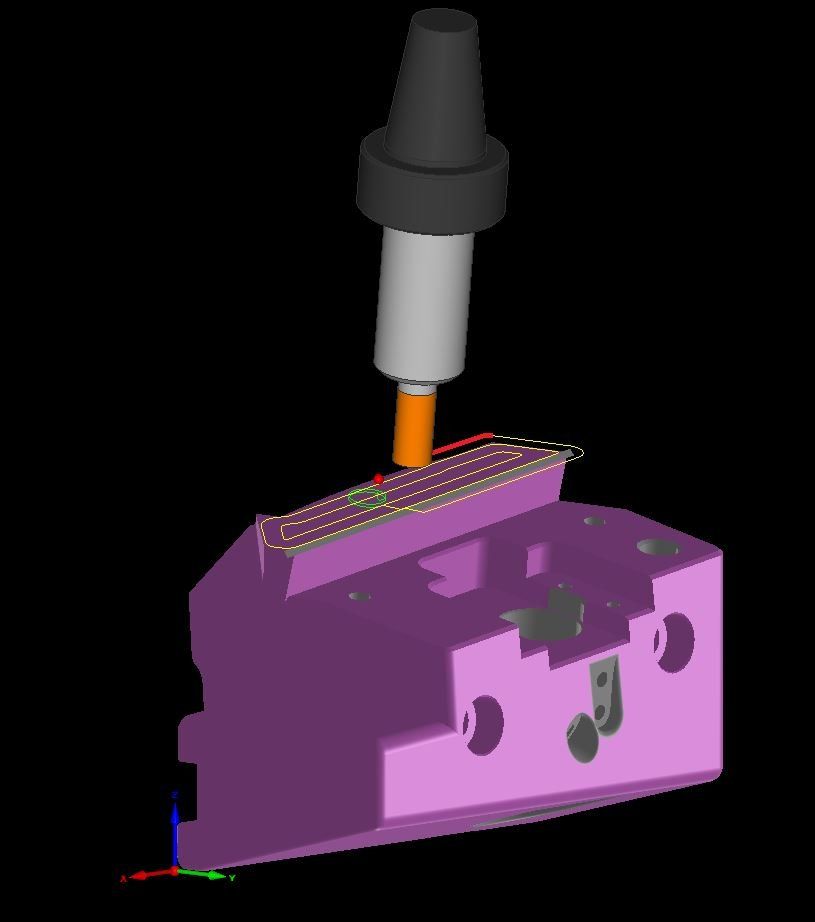

While using a PDM sever system several people can access the same data at the same time. Any changes to the model are then automatically updated including the NC Programs generated within the integrated SolidCam Software

Manufacture

The Manufacturing department comprises of:

- 4 DMG cnc machines with Renishaw part and tooling probe 5 Axis Ecomill 50 and 70

- 3 Axis DMG CMX 1100 v and 800v

- 3 Hurco cnc machines

- 1 VMX 50

- 2 VMX 30's

- 2 Spark Eroders

- Sodick AG60L

- Joemars A250R

- 5 Manual milling machines

- 2 DPM cnc milling machines

- Colchester lathe

- Jones Shipman 540p surface grinder

- Rapid prototype machine